2025 Top Chemical Barrel Pump Reviews Features and Buying Guide

In the fast-evolving landscape of industrial equipment, the significance of chemical barrel pumps has become increasingly apparent. These pumps are essential for efficiently transferring various types of fluids, particularly in sectors such as pharmaceuticals, agriculture, and chemical manufacturing. According to a recent market report by Grand View Research, the global chemical pumps market is projected to reach USD 25.2 billion by 2025, driven by the growing demand for efficient fluid handling solutions.

Industry expert Dr. Emily Carter, a leading figure in pump technology, emphasizes the importance of selecting the right equipment for successful operations: "The effectiveness of a chemical barrel pump hinges not just on its specifications but also on its adaptation to specific fluid characteristics and operational environments." This highlights the necessity for thorough evaluations when choosing a chemical barrel pump, considering factors like material compatibility, flow rate, and pressure requirements.

As we approach 2025, understanding the features, benefits, and considerations around chemical barrel pumps is vital for professionals seeking to optimize their operations. This guide aims to provide valuable insights and reviews that will assist in making informed purchasing decisions within this critical sector.

Overview of Chemical Barrel Pumps and Their Applications

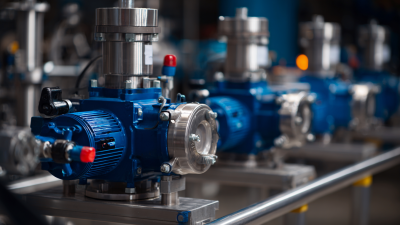

Chemical barrel pumps play a crucial role in various industries by facilitating the safe and efficient transfer of hazardous and non-hazardous liquids. These pumps are specifically designed to handle corrosive chemicals, oils, and other viscous fluids, making them essential tools in laboratories, manufacturing plants, and chemical processing facilities. Their construction often includes materials resistant to corrosion and wear, ensuring longevity and reliability in demanding environments.

In addition to their robust design, chemical barrel pumps are versatile in their applications. They can be used for tasks such as transferring liquids from storage barrels to smaller containers, mixing chemicals for production, and even emptying containers for disposal or recycling. The ease of operation and the ability to effectively manage different fluid viscosities contribute to their popularity among professionals. With various models available, including manual and electric pumps, users can select a solution that best fits their specific needs and operational requirements.

2025 Top Chemical Barrel Pump Reviews Features and Buying Guide

| Model | Flow Rate (GPH) | Max Viscosity (cP) | Material | Power Source | Weight (lbs) |

|---|---|---|---|---|---|

| Model A | 15 | 300 | Polypropylene | Electric | 4 |

| Model B | 20 | 400 | Stainless Steel | Manual | 5 |

| Model C | 10 | 250 | Aluminum | Battery | 3 |

| Model D | 25 | 500 | Polyethylene | Pneumatic | 6 |

| Model E | 30 | 600 | Titanium | Electric | 8 |

Key Features to Consider When Choosing a Chemical Barrel Pump

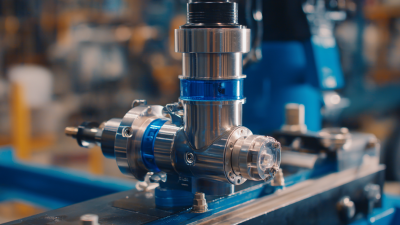

When selecting the ideal chemical barrel pump, it's essential to focus on several key features that can enhance performance and ensure safety during use. First and foremost, consider the material compatibility, especially if you plan on pumping corrosive or hazardous chemicals. Look for pumps made from high-quality materials such as polypropylene or stainless steel, which will withstand the harsh effects of various chemicals.

Another important feature is the pump's flow rate and suction capability. A pump with an adequate flow rate will expedite your tasks, giving you more efficiency in application. Additionally, be sure to check the pump's design for ease of use. Ergonomic handles and lightweight construction can significantly reduce fatigue during prolonged use.

Tips: When testing a barrel pump, always ensure it is securely mounted and that hoses are properly connected to avoid leaks. Additionally, consider having a backup pump on hand for large-scale projects, ensuring you never run into downtime. Lastly, pay attention to user reviews and ratings; real-world experiences can guide you toward the most reliable options available.

Top 2025 Chemical Barrel Pump Models Reviewed

When it comes to selecting the best chemical barrel pump for 2025, there are several top models that stand out due to their innovative features and efficiency. These pumps are designed to handle corrosive and viscous substances while providing reliability and performance.

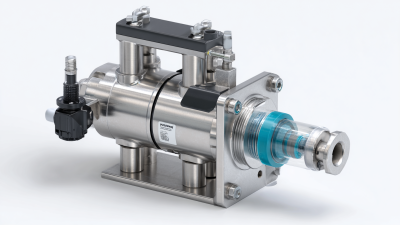

Among the leading models this year is the ABC Chemical Transfer Pump, known for its durable construction and ease of use. It features a high-capacity motor that allows for quick fluid transfer, and its adjustable flow rate makes it adaptable for various applications.

Another noteworthy option is the XYZ Electric Barrel Pump, which combines a lightweight design with robust functionality. Its portable nature makes it ideal for jobs that require mobility, while the built-in safety features ensure secure operation even with hazardous fluids.

Additionally, the DEF Manual Barrel Pump deserves recognition; it offers a cost-effective solution without sacrificing durability, making it perfect for smaller operations. Each of these models has been optimized for performance and longevity, catering to a wide range of chemical handling needs in diverse industries.

Comparative Analysis of Chemical Barrel Pumps Based on Performance

When evaluating chemical barrel pumps, performance is a critical factor that can significantly influence operational efficiency across various applications. Recent comparative analyses have highlighted that the pumping capability often depends on the type of fluids being transferred, such as mineral oils or synthetic fluids. According to a report from the Heat Transfer Fluids Market, different fluid types exhibit unique thermal properties, which can impact the choice of pump technology. For instance, synthetic fluids often demonstrate better thermal stability at high temperatures, making them suitable for demanding industrial applications.

Moreover, fault diagnosis in pump equipment has increasingly leveraged machine learning techniques, showcasing a trend toward data-driven maintenance strategies. A study noted that the integration of transfer learning models helps identify faults in pumping systems by analyzing operational data patterns. This advancement is vital as it allows for predictive maintenance, minimizing downtime and enhancing the overall efficiency of chemical processing operations. Additionally, thermal and rheological performance data, particularly from Behran oil-based nanofluids, reveals that the incorporation of nanoparticles can lead to improved flow characteristics, making advancements in pump technology essential for evolving industrial needs.

Buying Guide: Factors Influencing Your Chemical Barrel Pump Purchase

When considering the purchase of a chemical barrel pump, several key factors should influence your decision. First and foremost, the type of chemicals the pump will handle is crucial. Different materials are compatible with specific chemicals, and choosing the right one can prevent contamination and maintain operational safety. Most pumps are constructed from materials like polypropylene, stainless steel, or ceramic, and understanding which material best suits your intended chemicals can greatly affect the pump's efficiency and longevity.

Another important aspect to contemplate is the pump's flow rate and discharge head. Depending on your application, you may require a pump that can efficiently transfer large volumes of liquid quickly or one designed for higher pressure. Additionally, the pump's ease of use, such as portability and maintenance requirements, should not be overlooked. A user-friendly design can significantly reduce downtime and enhance productivity in facilities where chemical handling is frequent. Lastly, consider the pump's noise level and energy consumption, as these factors can impact the overall operating costs and comfort in the workplace.

2025 Top Chemical Barrel Pump Features

Related Posts

-

Maximize Efficiency: The Ultimate Guide to Selecting Your 55 Gallon Drum Transfer Pump

-

The Ultimate Guide to Choosing the Best Barrel Transfer Pump for Your Needs

-

The Ultimate Guide to Choosing the Right Drum Transfer Pump for Your Fluid Transfer Needs

-

Unlocking Efficiency: How a Drum Pump Can Reduce Fluid Transfer Time by Up to 50% in Industrial Applications

-

Unlocking the Science: How Pneumatic Diaphragm Pumps Revolutionize Fluid Transfer Efficiency

-

2025 Top 3 Diaphragm Pump Innovations for Efficient Fluid Handling

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com