Top 10 Benefits of Using a Pneumatic Drum Pump Today?

In today’s industrial landscape, efficiency and safety are paramount. The pneumatic drum pump has emerged as a crucial tool for many operations. According to a report by the Industrial Pump Association, over 70% of companies using pneumatic drum pumps noted significant improvements in their transfer processes. This highlights the relevance of pneumatic drum pumps in modern workplaces.

Expert Linda R. Thompson, an authority in fluid handling technologies, emphasizes, “The right equipment can transform a company's productivity.” Her insights underline the transformative potential of pneumatic drum pumps in various applications, from chemical handling to food production. These pumps not only enhance efficiency but also minimize spills and related hazards.

Despite their benefits, many organizations still overlook the importance of a pneumatic drum pump. This can lead to unnecessary risks and inefficiencies. Ignoring the advantages of pneumatic pumps could hinder growth. Investing in such technology is not just beneficial; it’s essential for keeping pace with industry demands. Addressing these challenges can unlock greater potential in operational performance.

Advantages of Pneumatic Drum Pumps Over Electric Pumps in Industrial Settings

Pneumatic drum pumps are increasingly preferred in industrial settings. Unlike electric pumps, they offer greater reliability and versatility. According to a recent industry report, nearly 80% of facilities favor pneumatic pumps for their durability and low maintenance needs. These pumps can operate in extreme conditions, including high temperatures and hazardous environments, where electric pumps may fail.

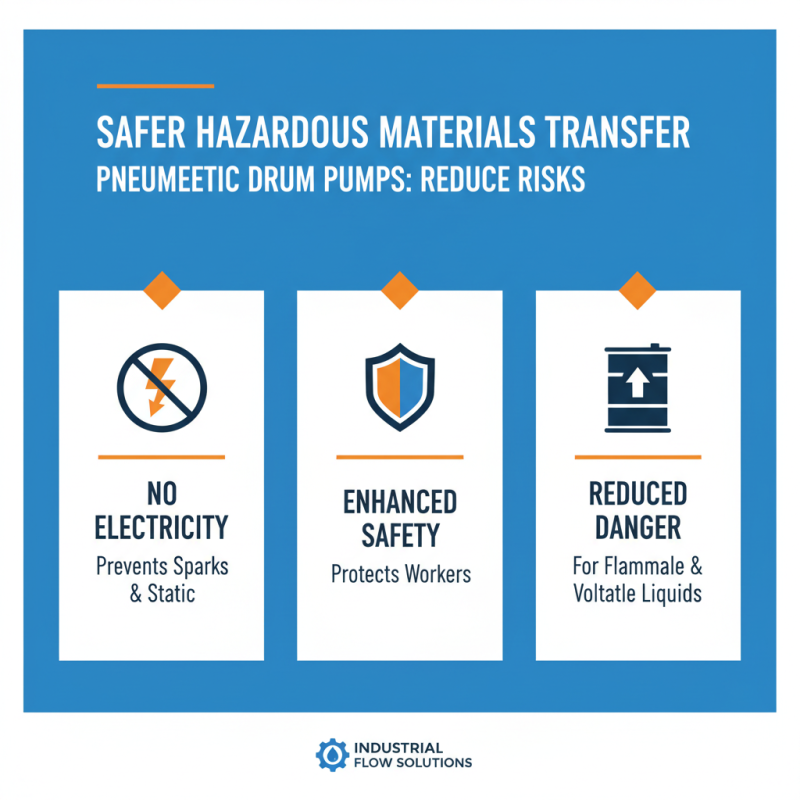

Safety is a critical factor in industrial operations. Pneumatic pumps significantly reduce the risk of sparks, eliminating fire hazards. They can easily handle flammable materials without the dangers associated with electric motors. A study found that pneumatic systems also consume less energy. They are often more efficient, saving facilities money on energy costs.

Flexibility is another advantage. Pneumatic pumps can be used with different liquids and solids, adjusting to diverse demands in various applications. However, this versatility can sometimes lead to mismatches in pressure settings. Operators need to be cautious and ensure proper adjustments. Over-reliance on these systems may cause issues if not regularly monitored and maintained. Addressing these points can improve overall pump performance and safety in the workplace.

Top 10 Benefits of Using a Pneumatic Drum Pump Today? - Advantages of Pneumatic Drum Pumps Over Electric Pumps in Industrial Settings

| Benefit | Description |

|---|---|

| Safety | Pneumatic pumps reduce the risk of electrical hazards in explosive environments. |

| Durability | Robust design withstands harsh industrial conditions better than electric pumps. |

| Efficiency | Higher flow rates significantly reduce the time needed for fluid transfer. |

| Maintenance | Lower maintenance costs due to fewer moving parts and simple structures. |

| Portability | Lightweight and easy to transport between different work sites. |

| Temperature Resistance | Able to handle a wide range of fluid temperatures without loss of performance. |

| Versatility | Can handle various fluids, including viscous and corrosive materials. |

| Environmentally Friendly | No oil leaks from electric components, reducing pollution risks. |

| Cost-effective | Lower operational costs due to energy efficiency and durability. |

| Quick setup | Fast to install and operate, reducing downtime in industrial processes. |

Efficiency Gains: How Pneumatic Drum Pumps Reduce Downtime in Operations

Pneumatic drum pumps are becoming essential in many industries. They offer significant efficiency gains. Reducing downtime is crucial for any operation. Traditional pumps often encounter issues that halt processes. Pneumatic pumps, however, can quickly start and stop without much hassle. This feature minimizes interruptions during fluid transfer.

Consider the time saved during maintenance. When a pneumatic pump needs servicing, it can be done without extensive downtime. Operators can refocus quickly on their tasks. These pumps also transport various fluids, saving time spent on pump switching. The versatility is a game changer. Yet, it’s essential to ensure proper training for operators. Inadequate knowledge can lead to mishaps. Constant evaluation of pump performance helps refine operational efficiency.

Installation can be tricky, and issues may arise. Ensuring correct setup can take time, which might frustrate personnel. However, with proper guidelines, these frustrations can be tackled. The gains from using pneumatic drum pumps often outweigh the challenges faced during initial implementation. Overall, they play a pivotal role in enhancing operational flow, keeping tasks on track.

Cost-Effectiveness Analysis: Operating Expenses of Pneumatic vs. Manual Pumps

When evaluating the operating expenses of pneumatic versus manual pumps, it's clear that cost-effectiveness plays a critical role. Pneumatic drum pumps offer a unique advantage by significantly reducing labor costs. Users can transfer liquids more quickly than with manual pumps. This quick transfer saves valuable time in industrial settings.

Energy consumption is another key factor. Pneumatic pumps typically use compressed air, which can lead to lower energy costs. However, maintenance costs can add up if not monitored closely. It may seem tempting to choose manual pumps initially due to their lower upfront price. But over time, the hidden costs can stack up.

It’s essential to consider productivity. A pneumatic pump can handle demanding tasks without fatigue. In contrast, manual pumps may require frequent breaks. Workers can become less efficient and error-prone when using manual methods for extended periods. Reflecting on these details can illuminate the disparities between pump types and guide better operational decisions.

Operating Expenses: Pneumatic vs. Manual Pumps

Safety Benefits: Minimizing Risks When Handling Hazardous Materials

Handling hazardous materials comes with significant risks. Using a pneumatic drum pump can greatly minimize these dangers. These pumps operate without electricity. This feature reduces the risk of sparks and static electricity. Consequently, workers are less exposed to potential dangers.

In addition, the design of pneumatic pumps often includes safety features. Many are equipped with automatic shut-off systems. This can prevent overfilling and spills. Spills can lead to slips and falls, a dangerous scenario. Furthermore, these pumps are generally easy to handle, promoting safer use in hazardous environments. Workers can focus on their tasks without worrying about potential accidents.

However, some might overlook maintenance. Failing to properly maintain pumps can lead to hazards. Regular checks ensure safety features are functioning as intended. It’s essential to inspect seals, connections, and hoses. A small leak can cause major problems. Reflecting on these aspects can further bolster safety for all involved.

Environmental Impact: Sustainability of Using Pneumatic Drum Pumps Today

Pneumatic drum pumps are gaining popularity due to their eco-friendly benefits. They use compressed air, which reduces electricity consumption. This change leads to lower carbon footprints. Many industries are now seeking sustainable solutions. There's a push for minimizing environmental damage. Using pneumatic pumps aligns with this goal.

Air-driven pumps can be more efficient, but they are not flawless. Sometimes, they can result in air contamination. This could potentially harm the liquids being transferred. Regular maintenance is critical to avoid these issues. Companies must ensure proper air filters are in place and regularly checked. Otherwise, the goal of sustainability may be compromised.

The portability of pneumatic pumps is another advantage. They can be easily moved and adapted to various settings. However, this flexibility also requires responsibility. Users must handle them with care to prevent spills. Promoting a culture of safety and awareness is essential. Eco-conscious facilities can lead the charge in sustainable practices. Integrating pneumatic drum pumps is a step towards a greener future, but continuous improvement is vital.

Related Posts

-

Discover the Hidden Benefits of Using an Air Drum Pump for Fluid Transfer

-

The Ultimate Guide to Choosing the Right Drum Transfer Pump for Your Fluid Transfer Needs

-

Unlocking Efficiency: How a Drum Pump Can Reduce Fluid Transfer Time by Up to 50% in Industrial Applications

-

Maximize Efficiency: The Ultimate Guide to Selecting Your 55 Gallon Drum Transfer Pump

-

Understanding the Advantages of Pneumatic Diaphragm Pumps in Industrial Applications

-

The Ultimate Guide to Choosing the Best Barrel Transfer Pump for Your Needs

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com