Top 10 Diaphragm Pump Applications for Efficient Fluid Transfer

Diaphragm pumps are pivotal in the realm of fluid transfer, offering a reliable and efficient solution across various industries. Their unique design, which utilizes a flexible diaphragm to create a vacuum and displace fluids, allows for handling a wide range of substances, including viscous, corrosive, and abrasive materials. This adaptability makes diaphragm pumps an indispensable tool in applications ranging from chemical processing to food and beverage manufacturing.

As industries strive for greater efficiency and reliability in their operations, understanding the diverse applications of diaphragm pumps becomes essential. This article explores the top ten applications of diaphragm pumps, highlighting how their robust performance and efficiency contribute to streamlined processes. By examining these applications, we can appreciate the crucial role diaphragm pumps play in enhancing productivity and ensuring the safe transfer of fluids in various settings.

Overview of Diaphragm Pumps and Their Functionality

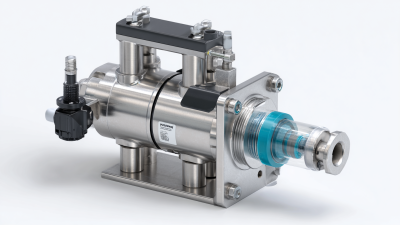

Diaphragm pumps are a type of positive displacement pump that utilize a flexible diaphragm to move fluids. They are well-regarded for their ability to handle a wide range of fluid types, including corrosive liquids, slurries, and viscous materials. The core functionality of diaphragm pumps rests in the reciprocating motion of the diaphragm, which creates a vacuum that draws fluid into the pump's chamber. As the diaphragm moves back, the chamber contracts and forces the fluid out through a discharge valve, ensuring a consistent flow. This design allows diaphragm pumps to operate effectively in many environments, including those requiring precise flow control and minimal leakage.

One of the most significant advantages of diaphragm pumps is their ability to run dry without damage, making them useful in applications where fluid availability is uncertain. Their self-priming capability allows for effective operation even in situations where the pump is installed above the fluid source. Additionally, diaphragm pumps offer versatility in fluid handling, making them suitable for various industries such as pharmaceuticals, food processing, and wastewater treatment. The combination of these features enhances their reliability and efficiency, positioning diaphragm pumps as essential tools for effective fluid transfer in industrial and commercial applications.

Key Advantages of Using Diaphragm Pumps for Fluid Transfer

Diaphragm pumps are increasingly favored for fluid transfer due to their unique design and the numerous advantages they offer. One key benefit is their ability to handle a wide range of fluids, including corrosive and viscous substances. This makes them particularly useful in industries such as chemical processing, food and beverage, and pharmaceuticals, where fluid properties can vary significantly. The diaphragm mechanism creates a seal that prevents backflow and contamination, ensuring product integrity, which is crucial in sensitive applications.

Another significant advantage of diaphragm pumps is their self-priming capability, allowing for efficient operation even when dealing with high-viscosity fluids. The robustness of these pumps allows them to operate in challenging environments, including those with high pressures or varying temperatures. Additionally, diaphragm pumps typically require less maintenance than other pump types, primarily due to their smooth, pulsation-free operation and fewer moving parts. This reliability not only reduces downtime but also lowers operational costs, making diaphragm pumps a smart choice for consistent and efficient fluid transfer across various applications.

Top Industries Utilizing Diaphragm Pumps for Efficiency

Diaphragm pumps are pivotal in several industries where efficient fluid transfer is crucial. Their versatility makes them a reliable choice in various sectors, including water treatment, chemical processing, food and beverage, pharmaceuticals, and oil and gas industries. In the water treatment sector, diaphragm pumps effectively manage wastewater and ensure consistent flow rates. In chemical processing, they handle corrosive substances without compromising safety or efficacy, while in the food and beverage industry, they maintain hygiene standards while transferring sensitive products.

When selecting diaphragm pumps for specific applications, consider flow rate and pressure requirements. It's essential to assess the compatibility of pump materials with the fluids being transferred. Additionally, monitoring the pump’s performance regularly can prevent unforeseen downtime.

For the pharmaceutical industry, precision and sterility are critical; diaphragm pumps excel in this area by providing accurate dosing and contamination-free transfer of liquids. In oil and gas, the robust design of diaphragm pumps ensures they withstand harsh environmental conditions while maintaining efficiency. By recognizing the unique needs of each industry, businesses can leverage the advantages of diaphragm pumps to enhance their operational efficiency.

Top 10 Diaphragm Pump Applications for Efficient Fluid Transfer

This chart showcases the top industries utilizing diaphragm pumps for efficient fluid transfer, highlighting their respective percentage shares in the market.

Specific Applications of Diaphragm Pumps in Chemical Processing

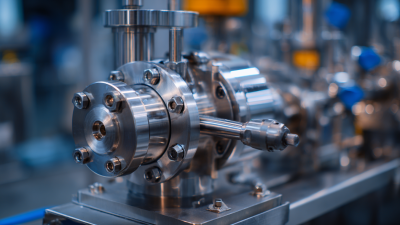

Diaphragm pumps have established themselves as a critical component in the chemical processing industry due to their unique ability to handle a wide range of fluids, including corrosive and viscous materials. One key application is in the transfer of acids and bases, where the pump’s design prevents contact between the fluid and the mechanical components, safeguarding both the equipment and operators. This makes diaphragm pumps particularly suitable for environments where chemical reactions or spills could pose serious hazards.

Another significant application of diaphragm pumps in chemical processing is in the dosing and metering of additives. Precise control over the transfer rate is essential in processes such as water treatment and the manufacturing of paints and coatings. Diaphragm pumps provide the accuracy needed to ensure consistent dosing, helping to maintain product quality while minimizing waste. Their ability to function effectively in various conditions, including high pressure and temperature, makes them a reliable choice for these critical operations.

Future Trends in Diaphragm Pump Technology and Applications

The advancement of diaphragm pump technology continues to play a pivotal role in optimizing fluid transfer across various industries. As demand for efficient and reliable fluid handling systems rises, leading industry reports indicate that the global diaphragm pump market is projected to reach approximately $5.8 billion by 2026, growing at a CAGR of around 5.6% from 2021. This growth is driven by the increasing emphasis on sustainability and the need for eco-friendly pumping solutions, especially in sectors such as pharmaceuticals, food and beverage, and wastewater management.

Future trends in diaphragm pump technology are likely to emphasize the integration of IoT and smart technology for enhanced monitoring and control. According to a report by MarketsandMarkets, the adoption of smart diaphragm pumps could reduce operational costs by up to 30% through predictive maintenance and real-time data analytics. Additionally, innovations in materials science are leading to the development of more durable and chemically resistant diaphragm materials, which will significantly extend the service life of these pumps while improving their performance in corrosive and abrasive environments. This evolution not only aligns with the growing regulatory standards for safety and efficiency but also opens new avenues for applications in emerging industries such as renewable energy and advanced manufacturing.

Top 10 Diaphragm Pump Applications for Efficient Fluid Transfer

| Application | Fluid Type | Pump Material | Flow Rate (L/min) | Pressure Range (bar) |

|---|---|---|---|---|

| Chemical Processing | Acids & Bases | Polypropylene | 10 | 2-7 |

| Food & Beverage | Hygienic Fluids | Stainless Steel | 15 | 1-5 |

| Water Treatment | Wastewater | PVC | 20 | 1-4 |

| Pharmaceuticals | Active Ingredients | EPDM | 8 | 3-6 |

| Mining | Slurries | Cast Iron | 30 | 1-10 |

| Marine Applications | Fuel & Oil | Aluminum | 25 | 1-8 |

| Construction | Concrete Additives | Rubber | 12 | 2-5 |

| Agriculture | Fertilizers | Polyethylene | 18 | 1-4 |

| Environmental Remediation | Polluted Fluids | Thermoplastic | 22 | 1-6 |

Related Posts

-

Unlocking the Science: How Pneumatic Diaphragm Pumps Revolutionize Fluid Transfer Efficiency

-

Understanding the Advantages of Pneumatic Diaphragm Pumps in Industrial Applications

-

Maximizing Efficiency with Small Diaphragm Pumps in Pharmaceutical Applications

-

The Ultimate Guide to Choosing the Best Barrel Transfer Pump for Your Needs

-

Why the Wilden Diaphragm Pump is the Best Choice for Reliable Fluid Transfer in Industrial Applications

-

Understanding the Benefits of Using Electric Drum Pumps in Industrial Applications

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com