The Ultimate Guide to Choosing the Right Drum Transfer Pump for Your Needs

In the industrial and commercial sectors, the efficient transfer of liquids is crucial for optimizing productivity and ensuring safety. Among the various tools available for this purpose, the drum transfer pump stands out as a versatile and essential device. According to a report by Grand View Research, the global market for drum pumps is projected to reach USD 2.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.3%. This growth underscores the increasing reliance on reliable pumping solutions across industries such as chemical manufacturing, food processing, and waste management.

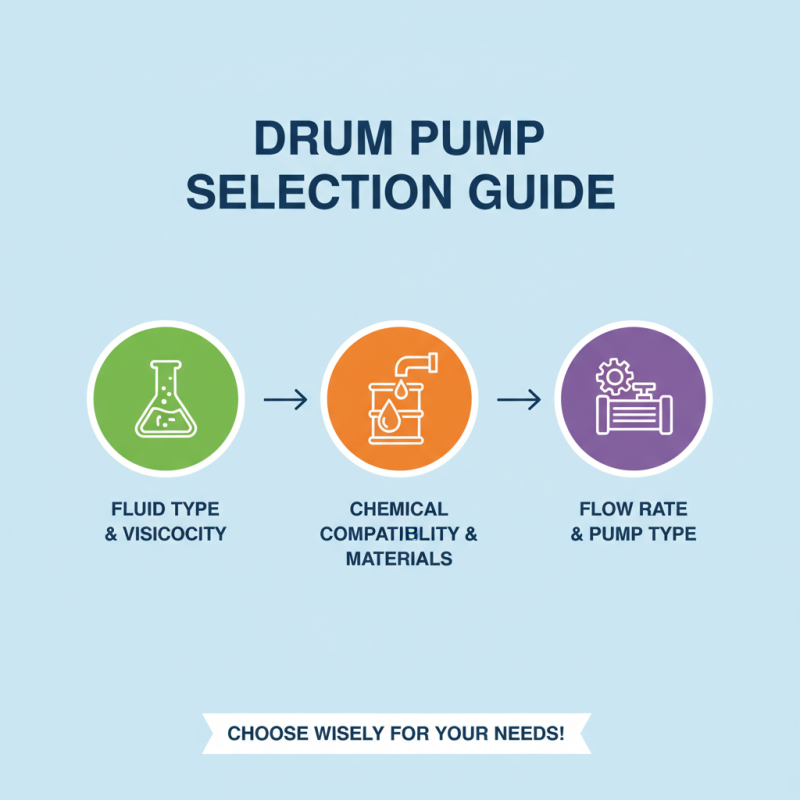

Selecting the right drum transfer pump involves understanding not only your specific application needs but also the characteristics and capabilities of the pumps themselves. Factors such as fluid viscosity, pump material compatibility, and operation efficiency are pivotal in determining the most suitable pump for your requirements. The importance of making an informed choice is further emphasized by data from the National Institute for Occupational Safety and Health, which highlights the need for effective liquid handling solutions to minimize workplace hazards associated with spills and overflows.

As you embark on the journey of choosing the ideal drum transfer pump, this guide aims to equip you with the necessary knowledge and insights to make a confident decision. By exploring key features, benefits, and best practices, you will be better prepared to select a drum transfer pump that not only meets your operational demands but also enhances overall safety and efficiency in your workplace.

Understanding the Functionality of Drum Transfer Pumps

Drum transfer pumps are essential tools for efficiently moving liquids from one container to another. Their primary function is to facilitate the safe and effective transfer of various fluids, including water, oils, and chemicals, without the risk of spills or contamination. These pumps come in various types, such as manual, electric, and air-operated, each designed to cater to specific needs based on the fluid's viscosity, volume, and transfer distance.

When choosing a drum transfer pump, consider the type of liquid you will be working with, as some pumps are better suited for thicker substances while others handle thinner fluids with ease. Additionally, pay attention to the transfer rate, compatibility with your drum size, and the pump's overall durability.

**Tips:** Always ensure that the pump you select meets safety standards relevant to the liquids being transferred. Regular maintenance and cleaning of your drum transfer pump can extend its lifespan and enhance its performance. Additionally, consider utilizing pumps with adjustable flow rates for more control over the transfer process, which can be particularly beneficial when dealing with sensitive liquids.

Key Factors to Consider When Selecting a Drum Transfer Pump

When selecting a drum transfer pump, there are several key factors to consider that will ensure you choose the right pump for your specific needs. First and foremost, assess the type of fluid you will be transferring. Different pumps are designed to handle various viscosities and chemical compositions, so it's essential to confirm that the materials and construction of the pump are compatible with the fluid. For example, if you are transferring corrosive substances, a pump with specific chemical resistance features will be necessary.

Another crucial aspect to take into account is the pump's flow rate and pressure capabilities. Determine the volume of fluid you need to transfer and how quickly you need to do it. A higher flow rate generally allows for more efficient pumping, but it’s important to ensure that the pump can maintain the necessary pressure throughout the operation. Additionally, consider the power source of the pump—whether electric, manual, or pneumatic—as this will impact its usability in your working environment. Ultimately, evaluating these factors will help you find a drum transfer pump that meets your demands effectively and safely.

Types of Drum Transfer Pumps and Their Specific Applications

When selecting a drum transfer pump, understanding the various types available and their specific applications is crucial for maximizing efficiency and safety in operations. There are mainly three types of drum transfer pumps: manual pumps, electric pumps, and air-operated pumps. Manual pumps are ideal for low-volume transfer tasks, making them a budget-friendly option suitable for small workshops. In contrast, electric pumps offer higher transfer rates and are preferred in industrial settings, where speed and efficiency are paramount. According to the latest industry report by the Fluid Power Institute, electric drum pumps can transfer fluids at rates exceeding 50 gallons per minute, significantly reducing downtime.

Air-operated pumps balance power and portability, making them versatile for transferring various liquids, especially in hazardous environments. Their explosion-proof design is highlighted in numerous safety data sheets, ensuring they can handle volatile substances without posing a risk. It's critical to assess the compatibility of your chosen pump with the specific fluid being transferred, including viscosity and chemical composition, as highlighted in the Chemical Compatibility Chart by the Chemical Engineering Society.

Tips: Always ensure the pump is rated for the liquid type you are dealing with to prevent equipment damage or safety hazards. Regular maintenance checks can prolong the life of the pump and ensure optimal performance. Moreover, invest in proper safety gear and training for handling fluids, particularly in industrial settings.

Safety Features and Maintenance Tips for Drum Transfer Pumps

When choosing a drum transfer pump, safety features should be a top priority. A report from the American Society of Safety Professionals highlights that nearly 30% of workplace injuries involving fluid transfer are due to equipment malfunction or improper use. Investing in pumps with automatic shut-off mechanisms, leak detection, and explosion-proof designs significantly reduces risk. Make sure to evaluate the materials used in construction, as corrosion-resistant components enhance longevity and safety when handling various chemicals.

Regular maintenance is crucial for ensuring the longevity and safe operation of your drum transfer pump. According to a study published by the International Journal of Industrial Ergonomics, pumps that undergo routine inspections and maintenance show a 50% reduction in failure rates. Users should routinely check seals and connections, clean filters, and perform lubrication as recommended by the manufacturer. Additionally, establishing a maintenance log can help track service history and spot potential issues before they escalate.

**Tips:**

- Always ensure that the pump is compatible with the specific chemicals being transferred, as improper compatibility can lead to leaks or corrosion.

- Make a habit of training all personnel involved in the operation of the pump, as proper training can drastically enhance workplace safety.

The Ultimate Guide to Choosing the Right Drum Transfer Pump for Your Needs

| Pump Type | Flow Rate (GPM) | Maximum Head (ft) | Power Source | Safety Features | Maintenance Tips |

|---|---|---|---|---|---|

| Electric Transfer Pump | 10 | 15 | Electric | Overload Protection, Thermal Cutoff | Regularly check for leaks, clean filters |

| Manual Hand Pump | 3 | 10 | Manual | Non-Sparking, Ergonomic Design | Inspect seals regularly, lubricate moving parts |

| Pneumatic Transfer Pump | 12 | 20 | Air Powered | Automatic Shut-off, Pressure Relief Valve | Keep air supply clean, check for wear on hoses |

| Battery Operated Pump | 8 | 12 | Battery | Low Battery Indicator, Waterproof Design | Store batteries properly, clean charging contacts |

How to Properly Install and Operate Your Drum Transfer Pump

When it comes to operating a drum transfer pump, proper installation is crucial for ensuring efficiency and safety. Begin by selecting a suitable location for the pump that allows easy access to the drum and adequate space for maneuvering. Make sure the surface is level and stable to prevent any accidental tipping or movement during operation. Always refer to the manufacturer's guidelines for specific installation requirements, including the proper alignment of hoses and connections.

Tips: Before starting the installation, inspect all components for any wear or damage that may affect performance. Having backup seals and gaskets on hand can save you time in case any parts need replacement upfront.

Once installed, thorough operation guidance is vital. Familiarize yourself with the pump’s controls and operating procedures. Start by ensuring that all safety features are engaged, and double-check that the drum is secure. Gradually prime the pump to avoid air locks, and monitor fluid levels regularly during operation. It is also important to maintain proper ventilation in the work area to mitigate any risks associated with fumes or spills.

Tips: Regularly clean the pump and surrounding area to prevent contamination. Schedule routine maintenance checks to prolong the life of the pump and ensure flawless operation each time you use it.

Related Posts

-

Maximize Efficiency: The Ultimate Guide to Selecting Your 55 Gallon Drum Transfer Pump

-

Unlocking Efficiency: How a Drum Pump Can Reduce Fluid Transfer Time by Up to 50% in Industrial Applications

-

Discover the Hidden Benefits of Using an Air Drum Pump for Fluid Transfer

-

Top 10 Best 55 Gallon Drum Transfer Pumps for Efficient Fluid Transfer

-

The Ultimate Guide to Choosing the Right Drum Transfer Pump for Your Fluid Transfer Needs

-

The Ultimate Guide to Choosing the Best Barrel Transfer Pump for Your Needs

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com