How to Choose the Best 55 Gallon Barrel Pump for Your Needs

When it comes to selecting the right equipment for fluid transfer, few tools are as essential as the 55 gallon barrel pump. Industry expert John Smith, a renowned authority in fluid management solutions, emphasizes, "Choosing the right barrel pump can significantly impact efficiency and safety in your operations." This statement underscores the importance of understanding your specific needs and the variety of options available in the market.

In various industries, from agriculture to manufacturing, a 55 gallon barrel pump can serve a multitude of purposes. Whether you are looking to handle chemicals, oils, or other fluids, the appropriate pump can streamline processes and prevent hazardous situations. Carefully evaluating factors such as material compatibility, viscosity of the fluid, and pump mechanism is crucial for effective selection. With an increasing demand for efficiency and safety in fluid management, understanding the nuances of these pumps is more important than ever.

This guide aims to equip you with the necessary knowledge to make an informed decision regarding your 55 gallon barrel pump selection. From understanding the different types and their applications to recognizing the vital features you should look for, we will explore how to ensure that the pump you choose meets your operational needs and enhances overall productivity.

Understanding the Different Types of 55 Gallon Barrel Pumps

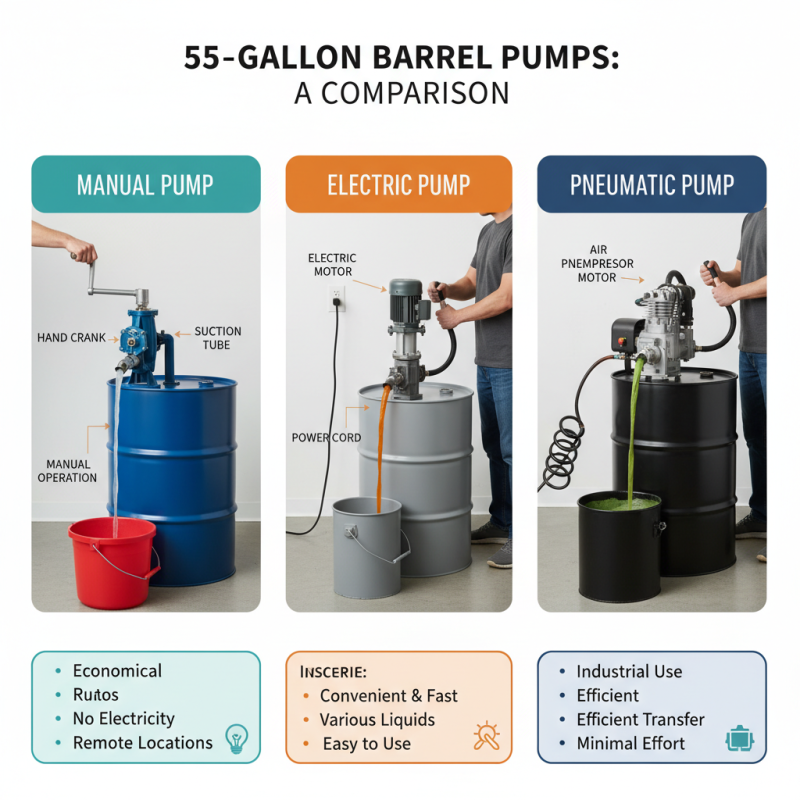

When selecting a 55-gallon barrel pump, it’s crucial to understand the different types available, as each is designed for specific applications. The most common types include manual pumps, electric pumps, and pneumatic pumps. Manual pumps are typically more economical and require no electricity, making them ideal for remote locations or situations where power is unavailable. Electric pumps, on the other hand, offer convenience and speed, often with the ability to handle various liquids. Pneumatic pumps are best suited for industrial settings where compressed air is readily available, providing efficient transfer with minimal effort.

When choosing a pump, consider the type of liquid you’ll be transferring. Some pumps are specifically designed for corrosive substances, while others are better for thicker fluids. It's essential to match the pump material to the liquid type to prevent any chemical reactions that could damage the pump or contaminate the liquid.

**Tips:** Always check the pump's flow rate and discharge pressure to ensure it meets your operational needs. Additionally, consider ease of installation and maintenance; a pump that is easy to operate and service will save time and resources in the long run. Lastly, assess the size and weight of the pump, particularly if portability is a factor for your usage needs.

Key Factors to Consider When Choosing a Barrel Pump

When selecting the best 55-gallon barrel pump for your needs, several key factors play a crucial role in ensuring optimal performance and safety. First, consider the materials that your pump will come into contact with. Pumps constructed from high-density polyethylene (HDPE) or stainless steel are typically preferred due to their resistance to corrosion and compatibility with various liquids, including oils, chemicals, and even food-grade substances. According to a recent industry report by the National Association of Manufacturers, corrosion can significantly reduce the lifespan of a pump, leading to costly replacements. Therefore, selecting a model that suits your specific fluid type will enhance durability and efficiency.

Another important factor is the pump's flow rate and compatibility with your existing systems. It's essential to assess the required flow rate based on the volume of liquid you need to transfer and the time frame for doing so. Many barrel pumps offer flow rates ranging from 5 to 25 gallons per minute (GPM), and choosing the right one can affect not only productivity but also energy consumption. A study by the American Society of Mechanical Engineers indicates that optimizing flow rates can lead to a 15% reduction in energy costs over time. Additionally, consider the pump's design features, such as ease of portability, the ability to operate in different orientations, and safety mechanisms like automatic shut-off valves, which are vital for minimizing risks during operation.

How to Choose the Best 55 Gallon Barrel Pump for Your Needs - Key Factors to Consider When Choosing a Barrel Pump

| Feature | Description | Importance Level |

|---|---|---|

| Flow Rate | The volume of fluid the pump can move per minute, typically measured in gallons per minute (GPM). | High |

| Material Compatibility | Ensures the pump can handle the type of fluid being transferred, such as water, chemicals, or oils. | Critical |

| Power Source | The energy source for the pump, which can be manual, electric, or pneumatic. | Medium |

| Suction Height | The maximum vertical distance the pump can lift fluid from the barrel. | High |

| Ease of Use | How user-friendly the pump is, including features like ergonomic design and ease of installation. | Medium |

| Durability | The longevity and robustness of the pump against wear and tear from repeated use. | High |

| Cost | The overall price of the pump, factor in maintenance, and replacement costs. | Medium |

Evaluating Pump Materials and Compatibility with Fluids

When choosing a 55-gallon barrel pump, one of the most crucial considerations is the pump material and its compatibility with the fluids you intend to handle. Different materials exhibit varying levels of resistance to chemical corrosion, temperature extremes, and mechanical wear, which can significantly impact the pump's performance and longevity. For instance, if you are working with corrosive substances like acids or solvents, using a pump made from high-quality plastics or stainless steel can ensure that the pump maintains its efficacy while preventing leaks and damage.

Additionally, it is essential to evaluate the fluid's viscosity and density, as these factors influence pump functionality. A pump designed for thin liquids might struggle with more viscous substances, resulting in inefficiencies or even pump failure. When selecting a pump, consider both the physical properties of the fluids and the environment in which the pump will operate. This alignment ensures that the pump not only meets your current needs but also adapts well to any changes in your fluid handling requirements over time. By thoroughly assessing these characteristics, you can choose a barrel pump that enhances productivity while minimizing maintenance issues.

Comparison of Barrel Pump Materials and Their Compatibility with Common Fluids

Assessing Pump Performance Metrics for Your Specific Needs

When selecting a 55-gallon barrel pump, understanding the performance metrics that align with your specific needs is crucial. The first essential metric to consider is the flow rate, which determines how quickly the pump can transfer liquids. Measured in gallons per minute (GPM), the flow rate will vary depending on the viscosity of the fluid and the pump's design.

For instance, lighter liquids may allow for higher flow rates, while thicker substances require pumps specifically engineered to handle their density without compromising performance.

Another vital metric is the pump's maximum pressure rating. This specification indicates the highest pressure the pump can handle safely without risking damage or failure. If you're working with pressurized systems or transferring liquids over long distances, a pump with a high-pressure capability is essential.

Additionally, consider the materials used in the pump's construction, as this will affect durability and compatibility with various fluids. Pumps made from corrosion-resistant materials are ideal for transferring aggressive chemicals, while those designed for general use may suffice for less caustic substances. Understanding these metrics will help you choose a barrel pump that effectively meets your operational requirements.

Maintenance Tips for Longevity of Your Barrel Pump

To ensure the longevity of your 55-gallon barrel pump, regular maintenance is essential. Begin with periodic inspections of the pump and its components, looking out for signs of wear and tear such as cracks, leaks, or corrosion. Pay special attention to the seals and gaskets, as these parts are crucial for preventing leaks and ensuring the efficiency of the pump. Regularly clean the pump to remove any residues or contaminants that could hinder its operation. A clean exterior also helps in identifying any potential issues early on.

Lubrication is another critical aspect of pump maintenance. Ensure that moving parts are adequately lubricated to reduce friction and wear. Follow the manufacturer's recommendations for lubrication frequency and type to keep the pump operating smoothly. Additionally, check and replace filters if applicable, as clogged filters can lead to performance issues. Lastly, educate yourself on the specific requirements of your pump model, as different types may have unique maintenance needs that can help maximize its lifespan. By implementing these maintenance tips, you can ensure that your barrel pump remains efficient and reliable for years to come.

Related Posts

-

Top 10 Best 55 Gallon Drum Transfer Pumps for Efficient Fluid Transfer

-

Top 10 Best Barrel Transfer Pumps for Efficient Liquid Transfer

-

The Ultimate Guide to Choosing the Right Drum Transfer Pump for Your Needs

-

Maximize Efficiency: The Ultimate Guide to Selecting Your 55 Gallon Drum Transfer Pump

-

The Ultimate Guide to Choosing the Right Drum Transfer Pump for Your Fluid Transfer Needs

-

Unlocking Efficiency: How a Drum Pump Can Reduce Fluid Transfer Time by Up to 50% in Industrial Applications

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com