How to Choose the Right Air Operated Double Diaphragm Pump for Your Needs

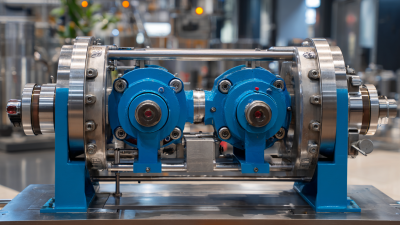

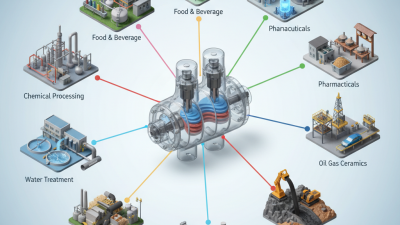

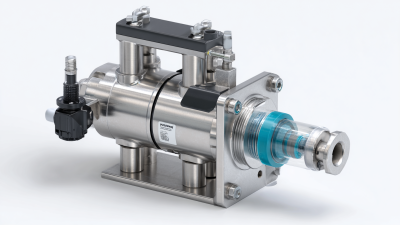

When it comes to selecting the right air operated double diaphragm pump for your specific applications, understanding the unique features and capabilities of these pumps is crucial. Air operated double diaphragm pumps are renowned for their versatility, ability to handle various fluids, and efficiency in transferring materials under different conditions. These pumps utilize a dual-diaphragm mechanism that allows for reliable performance and exceptional ease of maintenance, making them a popular choice across multiple industries, including chemical processing, food and beverage, and wastewater management.

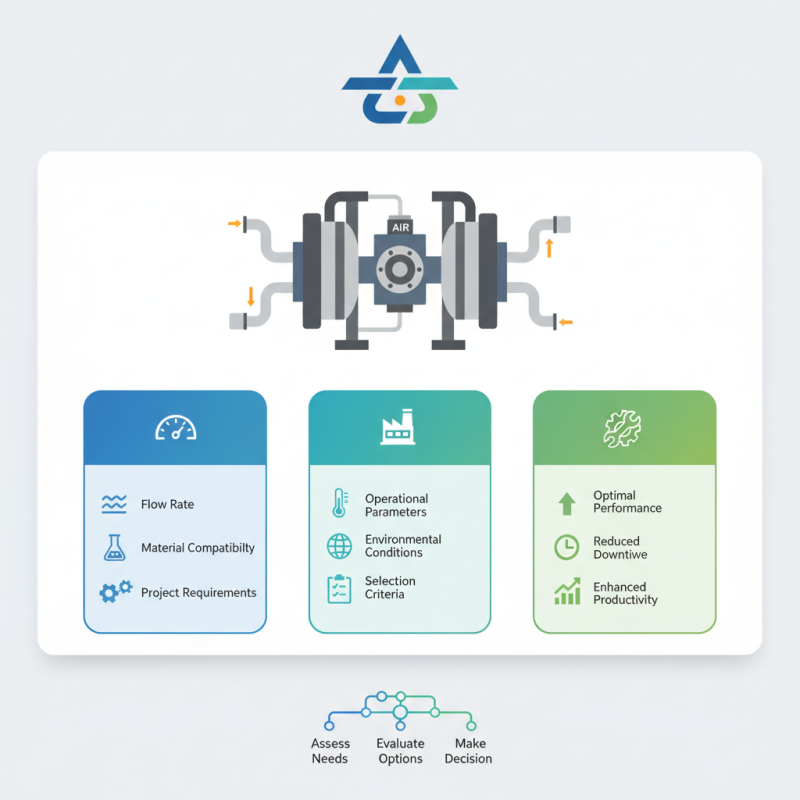

Choosing the correct air operated double diaphragm pump involves evaluating several key factors, such as flow rate, material compatibility, and the specific requirements of your project. With a myriad of options available on the market today, potential buyers must consider the operational parameters and the environment in which the pump will function. By carefully assessing each element, you can ensure that your selected pump will meet your operational needs and provide optimal performance, reducing downtime and enhancing productivity.

In this guide, we aim to simplify the selection process by outlining the essential criteria you should consider when choosing an air operated double diaphragm pump. By following this framework, you will be better equipped to make an informed decision that aligns with your pumping requirements and overall project goals.

Factors to Consider When Selecting an Air Operated Double Diaphragm Pump

When selecting an air-operated double diaphragm pump, several key factors must be taken into account to ensure that the pump meets specific operational requirements. First and foremost, consider the fluid characteristics. Assess the viscosity, temperature, and corrosiveness of the fluid being pumped. Different diaphragm materials and pump designs are tailored to handle various chemical properties and flow rates. Ensuring compatibility between the pump materials and the fluid will prolong the pump's lifespan and optimize performance.

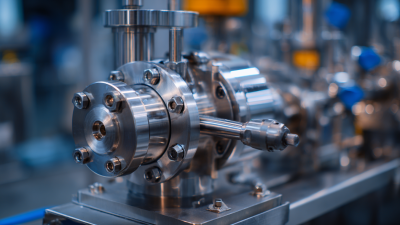

Another critical factor is the required flow rate and discharge pressure. Depending on the application, different pumps are designed to deliver varying rates of flow. It is essential to match the pump's performance specifications with the demands of the application to avoid issues such as cavitation or insufficient pressure. Additionally, evaluate the size and weight of the pump, as these elements can influence installation and mobility. Taking into account the available space and any specific site restrictions will help in choosing the right pump that not only fits physically but also integrates smoothly into existing systems.

Key Specifications to Evaluate: Flow Rate, Size, and Pressure Requirements

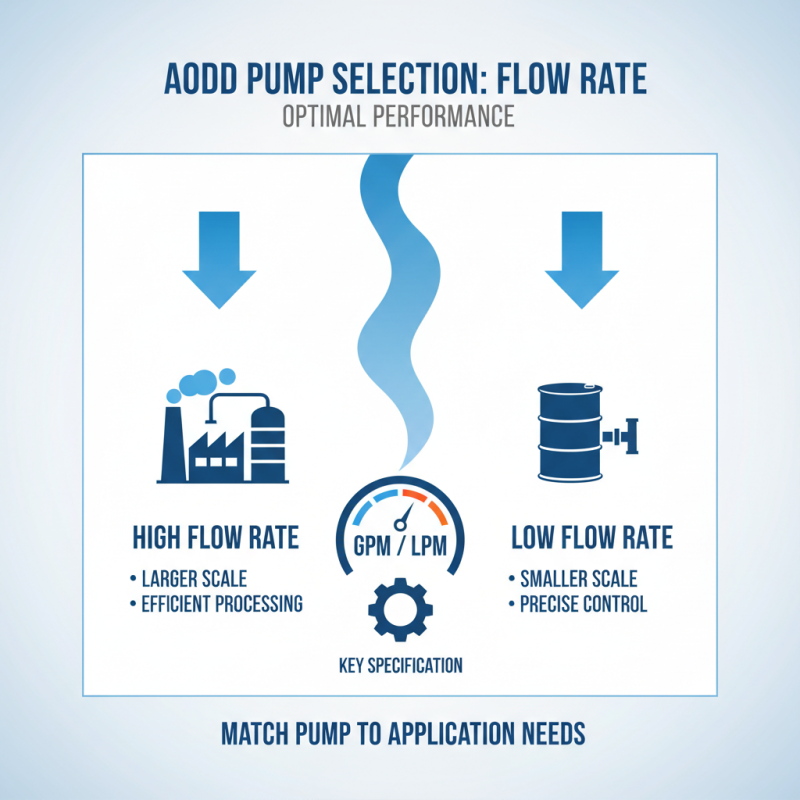

When selecting the right air operated double diaphragm pump, understanding the key specifications is critical for ensuring optimal performance in your application. The flow rate is one of the foremost factors to consider. It indicates how much fluid the pump can move over a set period and is typically measured in gallons per minute (GPM) or liters per minute (LPM). Depending on your operational needs, a higher flow rate may be necessary for larger scalability or more efficient processing, while smaller-scale applications may benefit from a pump with a lower flow rate.

Another essential specification to evaluate is the size of the pump. The physical dimensions can influence installation requirements, portability, and the workspace needed for operation. It's important to assess the compatibility of the pump with your existing setup to avoid any space-related issues. Additionally, pressure requirements should also be thoroughly examined, as they determine the pump's ability to handle different materials, viscosities, and the overall system performance. The right balance of size and pressure capabilities ensures that the pump will meet the demands of your specific applications without compromising safety or efficiency.

Material Compatibility: Choosing the Right Diaphragm and Wet-End Materials

When selecting an air-operated double diaphragm (AODD) pump, one of the most critical considerations is material compatibility, particularly in the diaphragm and wet-end components. The choice of materials can significantly affect the pump's performance, longevity, and overall efficiency. Research indicates that over 50% of pump failures are due to material-related issues, emphasizing the importance of selecting the right materials based on the application’s specific requirements.

Diaphragms are often made from elastomers or thermoplastics, each suited for different chemical environments. For instance, diaphragms made from PTFE are excellent for corrosive substances, while rubber-based options may be better for handling less aggressive fluids. A report by the Hydraulic Institute highlights that more than 30% of users experience chemical compatibility issues when using inadequate materials, leading to pump downtime and increased maintenance costs. Additionally, the wet-end materials must also be chosen carefully; stainless steels and certain plastics can withstand a range of pH levels and temperatures, making them versatile for diverse applications.

To ensure optimal performance, it's essential to evaluate not only the chemical properties of the substances being pumped but also factors such as temperature and pressure ranges. According to a study published in the Journal of Fluid Mechanics, properly matched materials can enhance the lifespan of pumps by up to 40%, leading to significant cost savings in industrial operations. Therefore, making informed decisions regarding diaphragm and wet-end materials is crucial for achieving reliable and efficient pumping solutions.

Understanding Application Needs: Chemical Resistance and Temperature Limits

When selecting an air operated double diaphragm (AODD) pump for specific applications, it is crucial to understand the requirements for chemical resistance and temperature limits. Many industries, such as pharmaceuticals and chemicals, frequently handle highly corrosive substances, making the choice of materials for the pump chamber and diaphragms critical. According to the 2022 Fluid Handling Equipment Technology Report, approximately 60% of operational failures in such applications can be traced back to inappropriate material selections that lack adequate chemical resistance.

Different types of polymers and elastomers, such as PTFE and EPDM, are commonly used in AODD pumps for their unique chemical compatibility profiles. For instance, PTFE excels in applications involving strong acids and bases, providing superior resistance to chemical attack, while EPDM is favorable for alcohols and certain solvents. The compatibility charts established by industry standards, like ASTM F739, guide engineers in selecting the right materials based on the specific chemicals being pumped, ensuring longevity and reliable performance.

Temperature limits also play a significant role, as many fluids are heated or cooled during processing. The same Fluid Handling Equipment Technology Report indicates that operating a pump beyond its temperature range can lead to reduced efficiency and increased wear, significantly affecting pump lifespan. Thus, confirming the maximum and minimum operating temperatures outlined by manufacturers is essential. High-temperature applications may require special materials, such as fluoropolymers, which can withstand elevated thermal conditions without compromising structural integrity. Understanding these parameters is vital for ensuring optimal pump performance tailored to specific application needs.

Maintenance and Longevity: Best Practices for Extended Pump Life

Proper maintenance is essential for ensuring the longevity of air-operated double diaphragm pumps. Regular inspections are key to identifying potential issues before they escalate. This includes checking for leaks, monitoring air supply pressure, and ensuring that all connections are secure. Keeping the pump clean is equally important; debris can clog the diaphragm and reduce efficiency. A thoughtful cleaning schedule will help maintain optimal performance and extend the lifespan of the pump.

In addition to routine inspections, lubrication of moving parts is crucial. Proper lubrication minimizes wear and tear, resulting in smoother operation and reduced downtime. It's also advisable to replace diaphragms and other wear parts periodically, as these components are subject to fatigue over time. By following these best practices, users can maximize the performance and reliability of their diaphragm pumps, ultimately leading to lower operating costs and fewer interruptions in their processes.

Related Posts

-

Unlocking Efficiency: The Science Behind Performance Optimization in Electric Double Diaphragm Pumps

-

Top 10 Diaphragm Pump Applications for Efficient Fluid Transfer

-

Understanding the Advantages of Pneumatic Diaphragm Pumps in Industrial Applications

-

Unlocking the Science: How Pneumatic Diaphragm Pumps Revolutionize Fluid Transfer Efficiency

-

Why the Wilden Diaphragm Pump is the Best Choice for Reliable Fluid Transfer in Industrial Applications

-

10 Essential Tips for Choosing the Right Air Operated Double Diaphragm Pump

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com