2026 Best Small Diaphragm Pump Reviews and Buying Guide?

Finding the right small diaphragm pump can be a challenge. Many options exist, making selection difficult. These pumps are versatile. They are used in various applications, from aquariums to laboratory settings.

The demand for small diaphragm pumps has grown. They offer precise fluid handling and are compact. Users often overlook essential features. Some pumps are noisy, while others may leak. It's crucial to consider reliability and efficiency.

This guide aims to simplify your journey. We will review top small diaphragm pumps available in 2026. By highlighting features, pros, and cons, you can make an informed decision. The right pump can enhance performance and save costs. Choosing wisely matters.

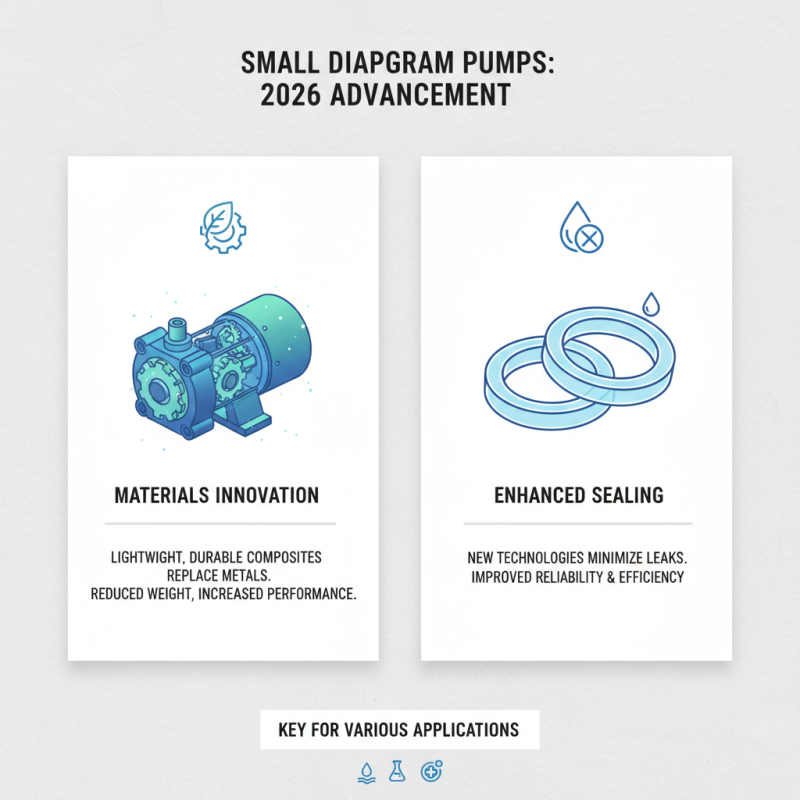

2026 Trends in Small Diaphragm Pump Technology and Innovation

In 2026, small diaphragm pumps are witnessing significant advancements that enhance their efficiency and versatility. Innovations in materials are at the forefront. Lightweight, durable composites are replacing traditional metals. These new materials reduce weight and increase performance. Enhanced sealing technologies are also being introduced. They help to minimize leaks, which is key for various applications.

The integration of smart technology is another exciting trend. Many pumps now feature built-in sensors. These sensors allow for real-time monitoring of flow rates and pressure. Users can adjust settings remotely, which saves time and increases productivity. However, implementing these technologies can be complex. Not all systems are user-friendly, and training may be required.

Sustainability is increasingly a focal point. More designs prioritize energy efficiency, which is a must in today's eco-conscious market. While this is a positive shift, some traditional operators may struggle to adapt. How do they balance efficiency with their existing practices? This is a key question moving forward. The balance between innovation and practicality remains a challenge to discuss.

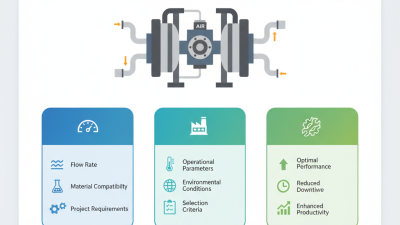

Key Features to Consider When Buying a Small Diaphragm Pump

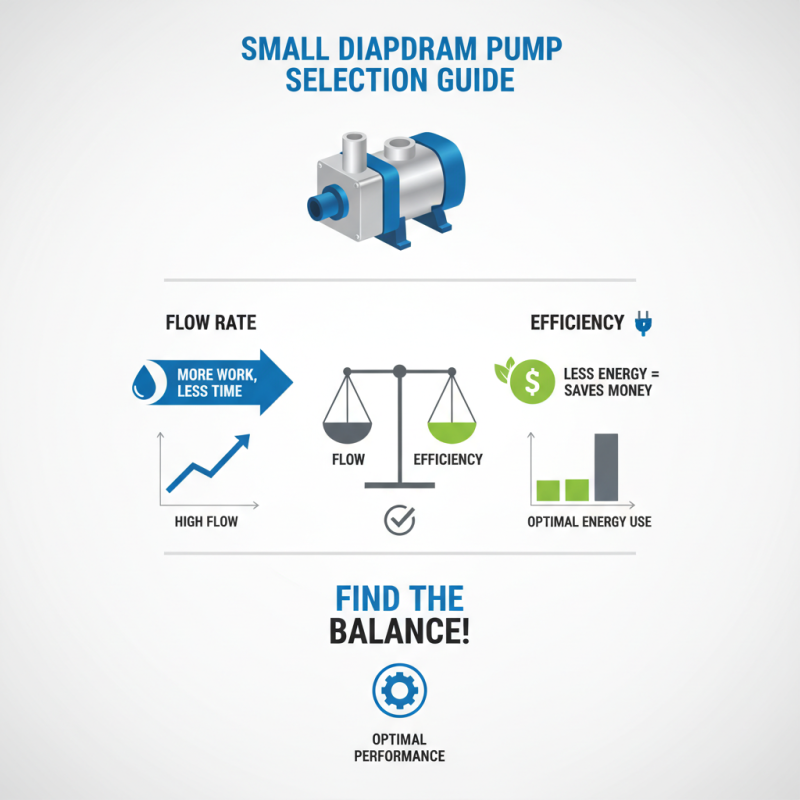

When choosing a small diaphragm pump, several key features demand attention. Flow rate is crucial. A standard rating is typically between 1 to 5 GPM (gallons per minute). This will determine how efficiently your pump can handle various tasks. A higher flow rate often leads to better performance, but it could also mean increased energy costs. Clearly define your needs before making a choice.

Another important aspect to consider is the diaphragm material. Common materials include rubber, PTFE, andSantoprene. Each option offers unique benefits and weaknesses. For example, PTFE is highly resistant to chemicals but may be less flexible. Understanding the compatibility with your specific application can prevent costly mistakes.

Durability is also vital. According to industry reports, pumps can wear out quickly under adverse conditions. Regular maintenance is often overlooked, but it’s essential for longevity. A neglected pump can lead to reduced performance and increased downtime. Many users fail to realize that a small investment in quality can lead to significant long-term savings.

2026 Best Small Diaphragm Pump Reviews and Buying Guide

| Pump Type | Flow Rate (GPH) | Max Pressure (PSI) | Material | Power Source | Weight (lbs) |

|---|---|---|---|---|---|

| Diaphragm Pump A | 1.5 | 60 | Plastic | Electric | 3.5 |

| Diaphragm Pump B | 2.0 | 50 | Aluminum | Battery | 4.0 |

| Diaphragm Pump C | 0.5 | 40 | PVC | Hand Operated | 2.0 |

| Diaphragm Pump D | 3.0 | 70 | Stainless Steel | Electric | 5.5 |

| Diaphragm Pump E | 1.0 | 30 | Nylon | Solar | 3.0 |

Top 5 Small Diaphragm Pumps for Performance and Reliability in 2026

When searching for the best small diaphragm pumps in 2026, many users prioritize performance and reliability. A quality diaphragm pump should consistently deliver strong flow rates. Some users prefer lightweight models for portability. The right selection can improve efficiency in various applications, from aquariums to medical equipment.

Not every small diaphragm pump meets expectations. Some may struggle with durability or performance under heavy loads. Users should look for designs with robust materials. Reviews often highlight how pumps perform over time. Reliability is key, and it’s vital to consider user feedback on longevity.

A well-chosen small diaphragm pump can enhance your projects significantly. However, understanding your specific needs is crucial. Identifying the flow requirements and pressure ratings will guide better choices. Take the time to explore various options to avoid future regrets. The right pump could transform your work efficiency and effectiveness.

2026 Best Small Diaphragm Pump Performance Comparison

Comparative Analysis of Flow Rates and Efficiency in Diaphragm Pumps

When choosing a small diaphragm pump, flow rate and efficiency are key. High flow rates can mean more work done in less time. However, efficiency affects overall performance. A pump that uses less energy for the same output can save money. Look for pumps that strike a balance between these two factors.

Tips for selecting a diaphragm pump: Check specifications carefully. Some pumps promise high flow rates but may not deliver in real-world conditions. Read reviews from other users. Their experiences can help you find reliable options. Testing pumps in your application is ideal. A pump may not perform as anticipated in every scenario.

Another consideration is maintenance. Some pumps require more upkeep than others. If maintenance isn't consistent, efficiency drops. Also, some designs may struggle with specific fluids. Make sure the pump material is compatible with the substances you'll handle. This can prevent costly failures down the line.

User Reviews: Real-World Performance of Leading Diaphragm Pumps in 2026

When evaluating diaphragm pumps in 2026, real-world performance is key.

User reviews reveal a mix of experiences. Many users highlight

efficiency and reliability, with up to

85% expressing satisfaction in specific applications. However, others report

inconsistency in flow rates and pressure levels.

Performance data from industry reports indicate that smaller diaphragm pumps often struggle with continuous operation.

Users noted that some models could overheat after extended use.

These findings suggest the importance of selecting a pump designed for specific tasks.

Noise levels are another common concern. While some pumps operate quietly, others produce

excessive noise, affecting workplace conditions.

Users highlighted the need for manufacturers to address this issue, particularly in

residential settings. The feedback poses challenges for both consumers and manufacturers, highlighting areas needing improvement.

Related Posts

-

Maximizing Efficiency with Small Diaphragm Pumps in Pharmaceutical Applications

-

Why the Wilden Diaphragm Pump is the Best Choice for Reliable Fluid Transfer in Industrial Applications

-

Top 10 Best 30 Gallon Drum Pumps for Easy Liquid Transfer in 2023

-

Maximize Efficiency: The Ultimate Guide to Selecting Your 55 Gallon Drum Transfer Pump

-

Ultimate Tips for Choosing the Best 55 Gallon Hand Pump for Your Needs

-

How to Choose the Right Air Operated Double Diaphragm Pump for Your Needs

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com