What is a 55 Gallon Hand Pump and How Does it Work Tips and Uses

A 55 gallon hand pump is a versatile tool designed for transferring liquids from large containers, commonly used in various industrial, agricultural, and household settings. Its simple yet effective mechanism allows users to extract liquids efficiently, making it an essential device for anyone who needs to manage substantial volumes of fluids. In this introduction, we will explore the functionality of a 55 gallon hand pump, detailing how it operates and the numerous advantages it offers.

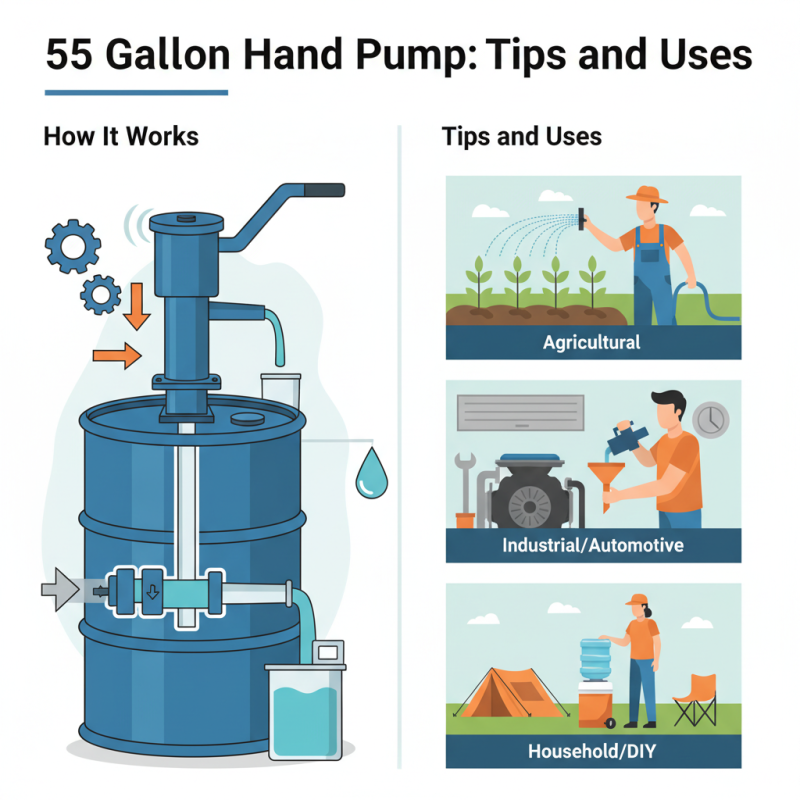

Understanding how a 55 gallon hand pump works reveals its practicality and ease of use. The pump typically operates through manual action, which means that users can control the flow rate and ensure precision in their operations. This feature is particularly beneficial when working with multiple liquids or when precise volumes are necessary. Furthermore, the pump is designed to work with a variety of fluids, making it a go-to tool for tasks ranging from liquid transfer during construction projects to dispensing water for irrigation.

In addition to its straightforward operation, there are countless applications for a 55 gallon hand pump. From managing situations in agricultural settings to serving as a crucial tool for DIY enthusiasts, this device proves invaluable in many contexts. This article will delve deeper into the tips and uses of the 55 gallon hand pump, guiding you on how to maximize its potential in your specific needs while ensuring safe and efficient liquid transfer.

What is a 55 Gallon Hand Pump?

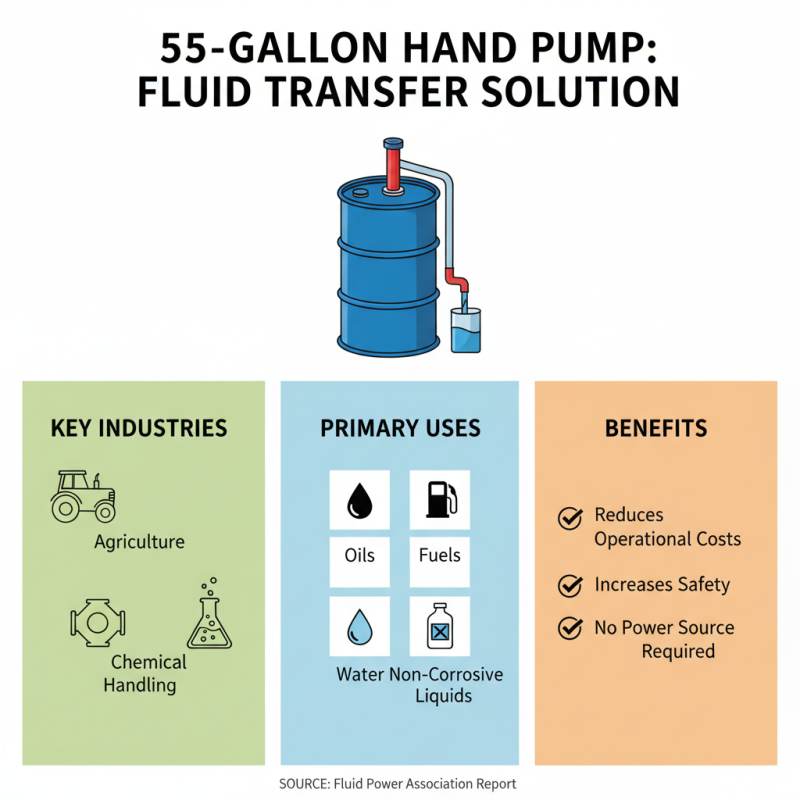

A 55-gallon hand pump is a mechanical device designed to transfer liquids from a large drum or barrel, typically utilized in industries such as agriculture, automotive, and chemical handling. These pumps are essential for efficiently dispensing large volumes of liquid, offering a convenient solution for transferring oils, fuels, water, and various non-corrosive liquids. According to a report by the Fluid Power Association, hand pumps like these are crucial in reducing operational costs and increasing safety in handling liquids, particularly in environments where power sources are limited.

The operation of a 55-gallon hand pump is relatively straightforward. Users engage a manual lever or handle to create suction, drawing liquid up through the pump and into the desired container. This technique not only minimizes spills but also ensures precise measurements during transfer. Data from market research by IBISWorld suggests that manual pumping systems have maintained a steady demand, driven by their ease of use and reliability in both commercial and residential settings. Moreover, the hand pump's portability makes it an invaluable tool in emergency scenarios where electricity and powered options may be unavailable, thus reinforcing its utility across various sectors.

Principle of Operation for Hand Pumps

The principle of operation for hand pumps, especially those designed for 55-gallon drums, revolves around a straightforward yet effective mechanism. At its core, a hand pump utilizes a combination of suction and pressure to transfer liquids from one container to another. When the handle is pulled up, it creates a vacuum within the pumping chamber, allowing liquid from the 55-gallon drum to flow into the chamber. When the handle is pushed down, this action forces the liquid out through a discharge spout.

The efficiency of a hand pump also lies in its simple construction, usually featuring a cylinder, a piston, and check valves. The check valves prevent backflow, ensuring that once the liquid is in the discharge line, it cannot return to the chamber. This mechanism is crucial for maintaining consistent flow and reducing waste. By continuously alternating between pulling and pushing the handle, users can effectively draw out the desired liquid for various applications, ranging from industrial uses to home water transfers. The ease of operation makes these pumps accessible for anyone needing to siphon liquids without the need for electricity or complex machinery.

Types of 55 Gallon Hand Pumps Available

When it comes to transferring liquids from a 55-gallon drum, hand pumps are a practical solution, offering versatility and efficiency. There are several types of hand pumps available, each designed for specific applications and liquid types. The most common types include rotary, diaphragm, and piston hand pumps.

Rotary hand pumps, for instance, are popular due to their ease of use and are commonly utilized for thinner liquids such as water or light oils. According to a market report from Smithers, the demand for rotary hand pumps has seen a steady growth of 4% annually, primarily due to their widespread utility in both commercial and industrial sectors.

Diaphragm pumps function through a flexible diaphragm that creates a vacuum, making them ideal for handling corrosive or viscous liquids. This type of pump is particularly useful in industries such as agriculture and chemical manufacturing, where chemical compatibility is crucial. Data from the Global Diaphragm Pump Market report indicates that the segment is projected to reach a value of $1.5 billion by 2025, driven by increasing safety standards and the need for reliable pumping solutions in hazardous environments.

Piston pumps are another notable type, renowned for their efficiency in transferring denser liquids. These pumps operate by using a piston mechanism, allowing for a strong discharge pressure, beneficial in applications such as fuel transfer and lubrication systems. The growth in the piston pump segment can be attributed to advancements in engineering materials that allow for higher performance and durability, projecting a growth rate of approximately 3.5% per year, as outlined in the latest industry analysis from MarketsandMarkets.

Common Applications and Uses of Hand Pumps

Hand pumps, particularly the 55-gallon variety, are versatile tools commonly used in various applications. One of the most prevalent uses is in industrial settings where bulk liquids, such as oils or chemicals, need to be transferred. These pumps offer a manual solution that does not require electricity, making them ideal for locations without power access. Users can efficiently dispense liquids from large storage containers, ensuring precise control over the amount dispensed.

In agricultural environments, 55-gallon hand pumps are indispensable for transferring water, fertilizers, or other liquid nutrients. Farmers often rely on these pumps to distribute resources effectively across their fields, providing the necessary sustenance for crops. They are also frequently employed in emergency situations, such as natural disasters, to supply clean drinking water when conventional infrastructure is compromised. The portability and simplicity of hand pumps allow them to be easily transported and operated, making them a critical tool in both routine operations and crisis management.

What is a 55 Gallon Hand Pump and How Does it Work Tips and Uses - Common Applications and Uses of Hand Pumps

| Feature | Description | Common Applications |

|---|---|---|

| Capacity | Designed for 55-gallon drums | Oil, chemicals, water transfer |

| Material | Typically made of durable plastic or metal | Various fluids including corrosive substances |

| Operation | Manual operation using a lever or handle | Fuel transfer, irrigation, liquid dispensing |

| Portability | Lightweight and easy to transport | Fieldwork, construction sites |

| Maintenance | Minimal maintenance required | Routine maintenance for longevity |

| Safety | Can be used safely with various fluids | Non-potable water, hazardous materials |

Tips for Proper Maintenance and Usage of Hand Pumps

Proper maintenance and usage of a 55-gallon hand pump are essential for ensuring its longevity and efficient operation.

First and foremost, regular inspection of the pump components is crucial. Check for any signs of wear or damage, particularly in the seals and hoses, as these can lead to leaks and loss of efficiency.

Lubricating moving parts as recommended in the manufacturer's directions can help reduce friction and prevent premature wear, ensuring smooth operation. Additionally, keeping the pump clean and free of debris will prevent potential blockages and make it easier to operate.

When using a 55-gallon hand pump, it’s important to understand the correct technique to optimize performance and minimize strain. Always place the pump on a stable, level surface and securely attach it to the barrel to prevent tipping.

Be sure to prime the pump adequately before use, as this allows for better suction and flow. When pumping, use even, steady strokes to maintain a consistent flow rate, which will also help in preventing overexertion.

After each use, consider emptying the pump of any remaining liquid to avoid corrosion and ensure it remains in good working order for future use.

Related Posts

-

Maximize Efficiency: The Ultimate Guide to Selecting Your 55 Gallon Drum Transfer Pump

-

Unlocking Efficiency: How a Drum Pump Can Reduce Fluid Transfer Time by Up to 50% in Industrial Applications

-

Understanding the Benefits of Using Electric Drum Pumps in Industrial Applications

-

Discover the Hidden Benefits of Using an Air Drum Pump for Fluid Transfer

-

Top 5 Benefits of Using a Barrel Hand Pump for Efficient Liquid Transfer

-

Top 10 Best 30 Gallon Drum Pumps for Easy Liquid Transfer in 2023

|

Need Help? Call Us 203-740-1877

|

We're ready to help identify, size and spec your pumps, filters |

All Products

Reliable Equipment Sales, LLC

Pumps, Parts, and Equipment – Guidance Included

103 Hempel Drive

Wolcott, CT 06716

Telephone: 203-740-1877

Toll Free Fax: 866-523-1693

Email: sale@rewritertool.com